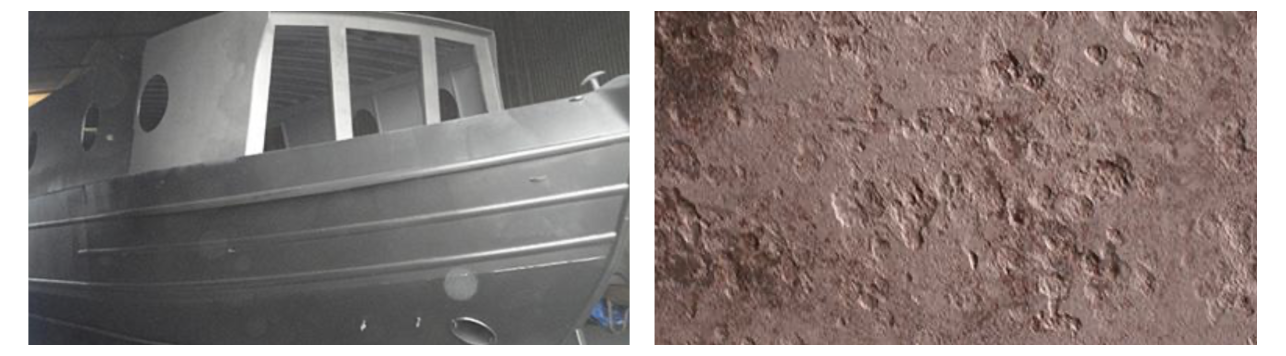

Shotblasting and Painting

Shot blasting removes mill scale from steel. It is imperative that the mill scale is removed from the steel prior to painting to ensure the longevity of the paint on your project or boat.

Mill scale is a type of iron oxide that is formed on the surface of the steel during the hot rolling process and is porous. The very high surface temperature combined with high roller pressures result in a smooth, bluish grey surface. If mill scale was a uniformly well-adhered covering to the steel section, then it would make an ideal protective barrier. Unfortunately, mill scale is not uniform, nor is it well-adhered.

This latter item is of concern, in that many projects have had high quality, expensive protective coatings applied directly over mill scale and inadequately prepared steel only to have the entire structure and coating system fail within a very short period of time.

Over the years we have treated many privately owned narrowboats and wide beams, some only after a few years after being built that haven’t been shot blasted and protected when originally built. Some of the pitting that arises from not having the steel shot blasted is rather distressing to the owners and in some cases leads to over plating the hull if left too long.

The mill scale in fact looks like a scale and it can “pop off” the surface, cracking the coatings of paint and allowing moisture to penetrate. This allows a galvanic reaction to occur which results in pitting corrosion (rust) to the base steel. This will result in a growth of the corrosion under the scale and produce further cracking to the coatings and expose greater areas and thus more corrosion.

All mill scale must be removed to present a uniform and clean surface.

Here at Awlworks Limited our steel surfaces are cleaned to a Sa 2.5 profile with an abrasive blast. This will remove the mill scale and provide a surface profile that will give the paint system its design requirements.

Painting over mill scale, however tempting, is a futile exercise, as the presence of mill scale on the steel surface accelerates the corrosion of the underlying steel.

Two Pack Paint Systems and Two Pack Blacking

Upon completion of shot blasting to Sa 2.5 we apply a two pack epoxy blacking up to the top rubbing strake (except base plate) on your boat or fully paint your steel project. The base plate can be shot blasted and a two pack epoxy blacking applied if required.

Interzone 954 is the ultimate high performance two pack epoxy blacking system from the leading paint specialists International Paint. Interzone 954 was formulated as a splash zone product and is used on high profile offshore installations globally.

Jotun 90 is also a two pack epoxy blacking system which provides long lasting protection in offshore environments and splash zones with high corrosivity.

Upon completion of shot blasting a boat to Sa 2.5 on the cabin sides, roof and deck areas, we apply a two pack high build, high performance epoxy primer, a two pack epoxy finishing primer, polyurethane undercoats, non slip coatings and polyurethane top coats in a wide range of colours.

The benefits of shot blasting and a two pack paint system are:

Under waterline

Interzone 954 and Jotun 90 are both harder wearing blacking. If Interzone 954 or Jotun 90 is scratched below the waterline, due to the indentation of the blast profile the damaged area will not spread unlike most conventional paint systems

Above waterline

Two pack acrylic – Alexseal range

Alexseal Acrylic X is a two component, fast drying acrylic coating with long lasting very high gloss and exceptional depth of image.

Provides an easy to apply, buffable finish, i.e. for small areas of tree damage, scratches can be buffed and polished back to its original condition, whilst also offering excellent colour stability values and additional resistance to UV rays salt water, abrasion and fuel.

Alexseal Acrylic X is also available in a range of metallic colours

Both of the above two pack systems are more commonly applied to Sunseeker and Princess super yachts giving you an excellent paint finish, not generally found on inland steel boats, nevertheless making sure your paintwork on your boat is the envy of your friends and long lasting.